Build Track's Bedford percussion longrifle parts set,

with 13/16", or 7/8" straight octagon barrel

|

|

Studying the longrifles of Bedford County, Pennsylvania, might cause you to imagine that time nearly stopped in Bedford County, or that this region was isolated from the world. How can we explain why these men continued to make Bedford County rifles for over 120 years, much later than we might expect? How can we explain these very odd locks, with long thin lock plates and "slash" molding decoration filed across a rattail? Why would the Bedford County makers laboriously hand file and hand fit each lock part, long after other makers were using purchased locks? Perhaps the answer is suggested in Calvin Hetrick's book The Bedford County Rifle and its Makers. The reason behind the success of any commercial enterprise is customer acceptance and demand.

Longrifles made in the region of Bedford County, Pennsylvania, are immediately recognizable. These rifles are long, thin, and graceful, with a low comb. Perhaps the customers of the Bedford County makers knew and liked this style, and demanded fine quality hand made flint locks. Or perhaps purchased locks would have altered the style of the gun too much to satisfy Bedford makers.

This fine Bedford County longrifle, signed by Michael Hayes of Park Rapids, MN, is constructed with fancy maple stock, brass furniture, L&R's percussion Bedford lock, and double set triggers. The engraved hand made patch box is copied from a original rifle by John Amos, shown in the book Pennsylvania Longrifles of Note, by George Shumway. The button release for the patchbox is hidden as one of the screws for the long toeplate.

We may never fully understand the reasons behind the unique appearance of Bedford County rifles. We know that rifles were made in Bedford County as early as 1776, and many were made between 1800 and 1890. This span makes the Bedford County rifle contemporary to the Brown Bess musket, the Hawken plains rifle, the Colt revolver, and even the Winchester lever action.

The book Gunsmiths of Bedford, Fulton, Huntingdon & Somerset Counties, by James B. Whisker & Larry Yantz contains numerous photos of fine rifles. This book is mostly wonderful photography of fine rifles, with close-up views of locks, engraving, fancy inlays, patchboxes, barrel signatures, and a few Bedford County powder horns. A invaluable resource in replicating a original rifle.

Order our Bedford County longrifle kit, and use your imagination. Plain or decorated, carved or inlaid, with double set triggers, many options are available. Each part is offered separately, so you can create your own custom rifle. Select the parts you need for your project in traditional brass, or nickel silver furniture. We recommend plain or fancy maple.

Colerain Barrel Company offers a select few calibers and octagon sizes in straight octagon barrels. Offered in .36, .40, .45, or .50 caliber depending on octagon size. Colerain straight octagon barrels are threaded to accept the breech plug.

Colerain rifle barrels are the favorite choice of today's best muzzle loading gun makers, because knowledgeable shooters demand Colerain's accuracy, inside and outside. Founded by two entrepreneurs, Scott Keller and Scott Kelly were tutored by Bob Paris, the famous rifle barrel maker who was first to perfect the technique for production of correct swamped barrels.

Colerain rifle barrels are cut rifled, with fancy radius groove rifling geometry, in correct twist rates for round balls:

- Cut rifled, with .012" to .016" deep grooves, depending on caliber.

- 1 turn in 48" twist, in .36, or .40 caliber.

- 1 turn in 56" twist, in .45, and .50 caliber.

Colerain rifle barrels are drilled from solid steel. Each barrel has six "round bottom" grooves, called "radius groove rifling". Colerain eliminates the sharp inside corner that accumulates fouling. Radius groove rifling cutters are a bit more expensive to make, but Colerain's customers agree that the accuracy, easy loading, and easy cleaning are worth the cost.

Stocks,for our Bedford County longrifle were designed by the well respected maker Michael Hayes. Shaped and pre-inlet on the high precision Allen's Patent 5 axis pantograph, this slim fullstock is inlet for L&R's flint Bedford County lock, and a 13/16", or 7/8" straight octagon barrel channel. Lock panels are crisp; the forend is squared. Inlet for our buttplate, and L&R's Bedford double set triggers. Drop is 3-3/4" from the line of sights to heel, at 14" length of pull. 1-1/2" wide by 4-1/2" high, cut for buttplate.

We offer a complete set of brass furniture, to fit this rifle. Furniture includes the buttplate, triggerguard, toeplate, forward and entry ramrod pipes, sideplate, ramrod, and ramrod tip. As cast, the castings need to have the casting gates removed by filing or grinding, and must be polished, then drilled for mounting screws, as needed. Bedford County longrifles often have numerous inlays, be sure to check out the many inlays we offer to complete the decoration of your rifle.

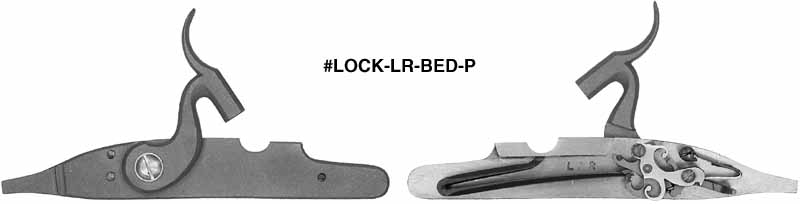

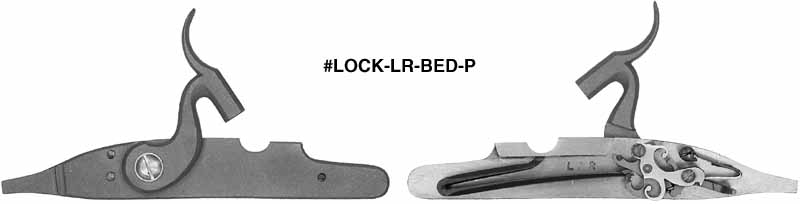

L&R's percussion lock captures the essence of the Bedford County rifle, after this distinctive style of lock had been clearly established. Most photos of Bedford County rifles show percussion locks, but flint locks are known. Calvin Hetrick names several makers of flint rifles, including Joseph Mills of Colerain Township, who is little known except for his superior workmanship. All known specimens of his work were originally flint ignition.

Inside, the tumbler and sear have raised bearing rings turned around each axis of rotation, holding the parts away from the plate, to minimize friction, and speed up ignition.

A fly detent is fitted to the tumbler's mortise, preventing the sear from accidentally engaging the half cock notch when fired. Suitable for use with plain or double set triggers, on rifle barrels as small as 3/4" or as large as 1" octagon.

This nice lock shares internal parts with other fine L&R locks. Notice the "cutaway" tumbler and "swing out" link, which simplify disassembly of the lock for cleaning. Always reassemble the link in the 'S' orientation, with the small end at top, when viewed from inside. Never assemble the link back-wards, else the tumbler will break!

The lock plate is polished inside. Exterior parts are gray matte grit blasted, ready for browning. Internal parts come close to the edge of the plate. Don't be tempted to over-inlet moving parts.

Powder drum, #DRUM-7-5-F-L, we now offer powder drums with a removable lug for installation. Not drilled for the nipple, use our #TOOL-DRUM, drum drilling jig to make this step easy. After the drum is installed, simply cut off the lug and the drum will appear just as those found on original percussion longrifles.

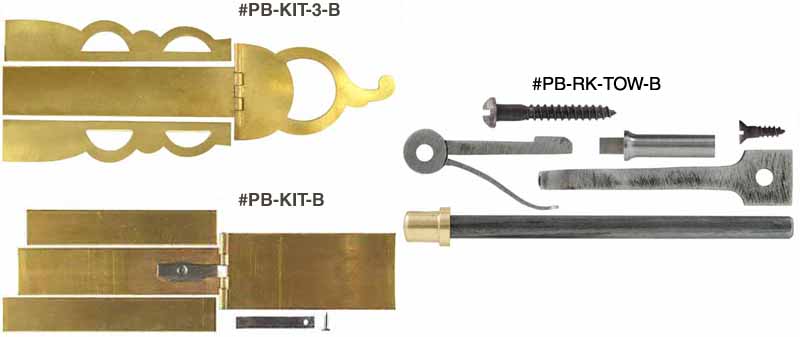

Although not required, patchboxes are often fitted on Bedford County, Pennsylvania longrifles. We offer a number of correct choices, which may be installed with cam over center springs or button release kits at extra cost.

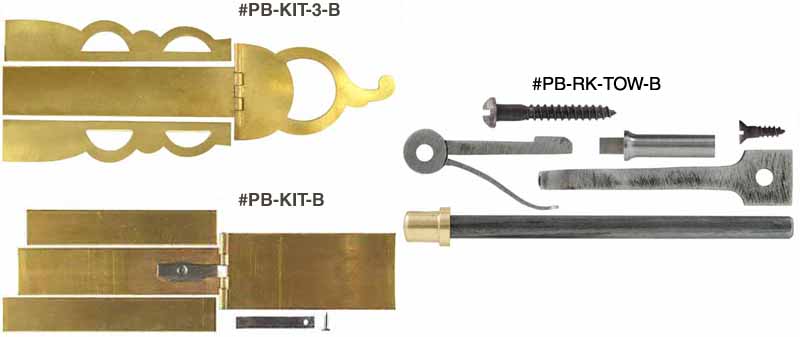

#PB-KIT-3-B or S: Copied from a rifle made and signed by Jacob Stoudenour, 1795-1863. Shown in Gunsmiths of Bedford, Fulton, Huntingdon & Somerset Counties. Springs and instructions are included. 7-1/2" overall length.

#PB-KIT-B or S: Curved to fit your buttstock, neatly hinged with steel cam finger inside the lid, cam spring and mounting screw. We show the rough underside to reveal the features. Polished outside, the curved hing fits well. Made of .052" thick sheet brass. The flat spring is tempered, ready to use, it may be finger soldered under the lid. Use this blank kit to copy an original. 7-3/4" overall length.

#PB-RK-TOW-B or I: This high quality patchbox release kit is made for use with brass, iron, or nickel silver patchboxes. The kit includes four precision steel parts, two unplated steel screws, and fully illustrated instructions. Made with your choice of a brass or steel release button.

Gunsmithing Labor Options are a popular low cost method of speeding assembly. Our gunsmith can install the plug (#LABOR-BP) front and rear sights (2 #LABOR-DS), and underlugs (3 #LABOR-UL) at small extra cost, with prompt delivery.

#LABOR-BP: Our gunsmith will install your breech plug, in your barrel, with the front face of the breech plug tightly sealed against the inside shoulder of the breech thread, and the barrel maker's name indexed to the bottom flat. Threads are lubricated with Birchwood Casey's Choke Tube Lube anti-seize, so the plug may be removed, even after decades of use. Never remove a breech plug, unless you have a compelling reason. The plug is never removed for cleaning, and should only be removed by a skilled gunsmith, who has the correct tools to avoid marking your polished and finished barrel and plug.

#LABOR-DS: When you buy the sight from us, we will remove any burrs, gates, or parting lines, and hand fit the sight to the dovetail slot, ready for you to finish and use. Many of our rear sights are cast with an oversize base, to allow these to fill oversize slots. It is wise to allow us to trim these to a standard size, before installation in a new barrel. We must install the breech plug before installing sights, rib, or pipes.

Front sight slots are centered 1.5" from muzzle, unless your clearly specify another location. Do not embed special instructions within lengthy text of a letter. Place special instructions immediately after your written order for that item, or in the comment field of our on-line order form.

Rear sight slots are centered 8.5" from the breech end of the barrel (not including plug), unless your clearly specify another location. Do not embed special instructions within lengthy text of a letter. Place special instructions immediately after your written order for that item, or in the comment field of our on-line order form.

#LABOR-UL: When you buy the lugs from us, we will remove any burrs, and hand fit the lug to the dovetail slot, ready for you to finish and use. Allow our gunsmith to determine the best location for lug. Typically these rifles require three lugs. We require the breech plug to be fitted before performing this operation.

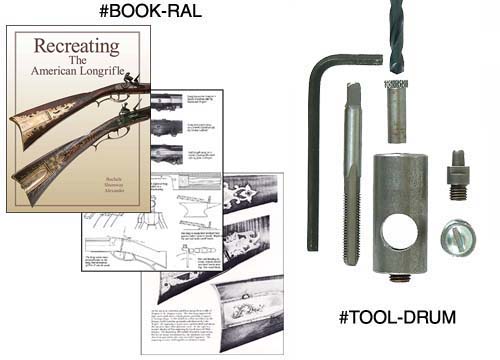

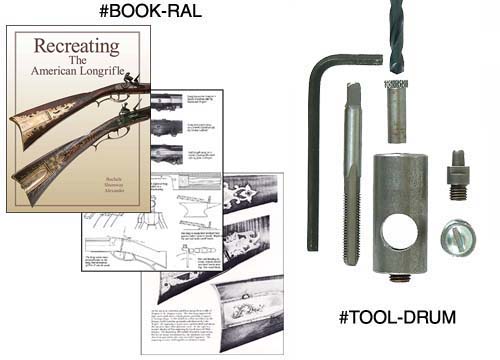

#BOOK-RAL: If you have never built a rifle from scratch we recommend the book Recreating the American Longrifle. The late William Buchele was recognized as a true master longrifle maker. But his greatest contribution to muzzle loading must be this book. He shares the step by step details of his craft. His work has been enhanced by the editors. This book does not assume that the reader is an expert stock maker, but begins with illustrated explanations of the basic concepts. Buchele shows several alternate approaches to most tasks. Newly revised edition.Full scale plans include a carved longrifle and fullstock pistol. Over 250 photos and drawings within the 176 pages, 8-1/2 x 11" format, soft cover.

#TOOL-DRUM: Use Track's drum drilling jig to install a percussion powder drum on your new rifle barrel, and be assured of perfect alignment. Using this drilling jig is very quick and easy. No file fitting is required to index the nipple to correctly engage the hammer. Never use a washer or shim under your powder drum. Install one of our drums and use this tool to locate and install the nipple threads. After your lock is correctly located, and fully inlet against the barrel's side flat, drill tap and install our undrilled powder drum. Tighten it snugly against the barrel. Lower the hammer on your lock, and draw a line across the face of the drum, showing the proper nipple angle. Remove the barrel and drum assembly from your stock. Slip this tool over the drum. Align it with the line on your drum. Tighten the locking screw, and insert the drill bushing. Using your hand drill and your #3 drill bit, drill a connecting hole into the powder drums center channel. Remove the drill, bushing, and insert our 1/4-28 plug tap. Using a tap handle and cutting oil, thread the hole to accept our #RST-A nipple. Finish with our bottom tap. Dismount the drill jig, and proof test your barrel and drum before use. Drill, taps, drum and nipple sold separately.

We also recommend our new catalog, which describes this kit in great detail, explains the options, and shows most individual parts in exact full size photographs. Prices may change, over the years, but the technical data, dimensions, instructions, and precise photos will make this 432 page book an essential too on your work bench.

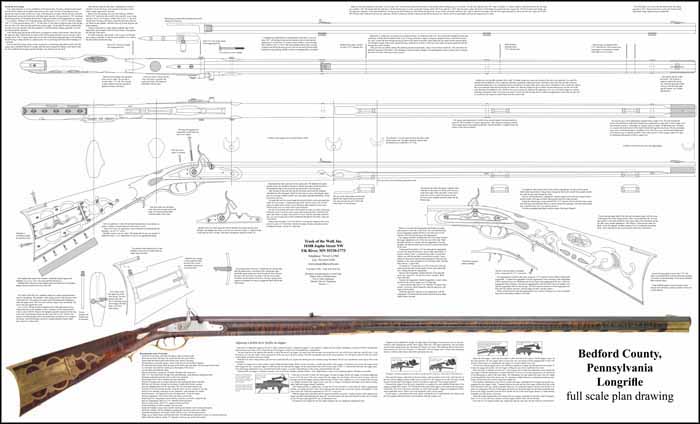

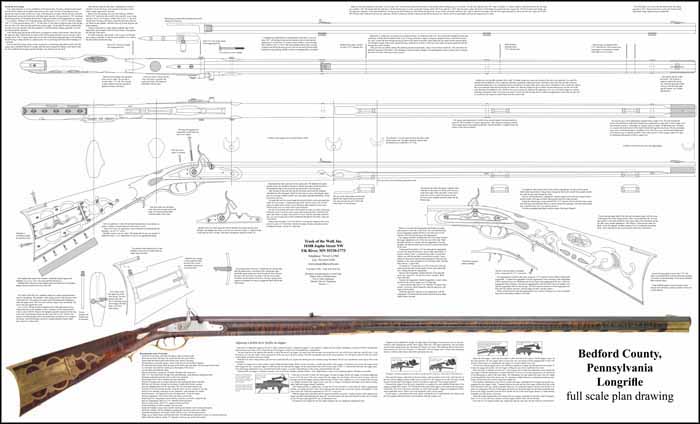

#PLAN-BEDFORD These plans will allow you to replicate a Bedford County longrifle, using our L&R Bedford flint or percussion lock, stock, barrel and castings. These slim longrifles are unique to the Bedford County area, where they were made from the flint era until the 1880's, long after the advent of cartridge rifles. Neatly drawn and dimensioned, with some tips to aid assembly. We also recommend Gunmakers of Bedford, Fulton, Huntington & Somerset, Counties. This book reveals Bedford County rifle details, in close-up photos.

Typically 40 hours of skilled labor is required to build a longrifle rifle. Drilling and tapping is required. Use of a drill press in recommended. A skilled mentor, as always, can be a invaluable aid in building any rifle.

Gun building is fun! Click to view the prices and options. Choose the options ADD TO CART and complete checkout to send your order, for same day shipment.

Track of the Wolf, Inc.

18308 Joplin St NW

Elk River, MN 55330-1773

Copyright ©

2025 Track of the Wolf, Inc.